|

Product Details

Products : API 5CT Casing Tube and Tubing BTC STC LTC VAM Connection for Oil well Petroleum Special Casing

Product Description:

API 5CT J55 Oil Tubing

Usage :

Tube for vonveying gas, water and oil in both and natural gas industries etc .

Quality standard :

API 5CT Casing and Tubing

BS EN ISO 11960 ,NF M87-207 , JIS G3439 , IS:4270

Steel Grade :

H-40 ,J-55 ,K-55,N-80,C-75,L-80,C-90,T-95 ,Q-125

Process : ERW and seamless

Size :

Outside diameter : Casing pipe : OD 4/1-2" -20 " (114.3mm-508mm)

Tubing : OD2-3/8"-4-1/2" (60.3mm-114.3mm)

Wall thickness : 0.205"-0.635"

Length : R1 Casing pipe: 4.88 ~ 7.62m, R2 Casing pipe : 7.62 ~ 10.36m, R3 Casing Pipe : 10.36m to longer.

End : Bevel end , square cut and pipe protection cap specially for casing and tubing .

Surface : Corrosion proofing water based paint .API Oil Tubing

Thread : BTC Casing Pipe , VAM ,NEW VAM ,STC,LTC,VAM TOP, STJ-SN, STJ-ST, JIP,JIP FLISH MAX ,SUPPER MAX, GEO, PPCM, TMK, HUNTING, RTS-8 , RTS-6, RTS-5 ,WPS THREAD Follow API 5CT and API 5B standard .

Normal size range of coupling stock :

|

Labels |

OD(mm) |

WT(mm) |

|

2 3/8 |

72 |

12 |

|

2 3/8 EU |

78 |

12 |

|

2 7/8 |

89 |

13 |

|

2 7/8 EU |

94 |

13 |

|

3 1/2 |

108 |

15 |

|

3 1/2 EU |

114 |

15.5 |

|

4 |

121 |

15.5 |

|

4 EU |

127 |

16 |

|

4 1/2 |

132 |

15.5 |

|

41/2 EU |

141 |

15 |

|

5 |

141 |

14.5 |

|

5 1/2 |

154 |

14.5 |

|

6 5/8 |

188 |

15 |

|

7 |

195 |

17 |

|

7 5/8 |

216 |

19.5 |

|

8 5/8 |

245 |

21.5 |

|

9 5/8 |

270 |

21.5 |

|

10 3/4 |

299 |

21.5 |

|

11 3/4 |

324 |

21.5 |

|

13 3/8 |

365 |

25.4 |

|

16 |

432 |

22 |

Package : Steel bundle ,Protector on both end .hexagonal bundles of max. 2000kgs with several steel strips , two tags on each bundle , wrapped in waterproof paper , PVC sleeve and sackcloth with several steel strips . Casing and Tubing

Heat treatment : Normalized , Quencher+Temper

Test : Chemical Component Analysis , Mechanical Properties (Ultimate tensile strenth ,Yield strenth ,Elongation )

Technical Properties ( Flattening test , flaring test , bending test , hardness test , blow test , impact test etc )

Exterior size inspection , Nondestructive test ( Ultrasonic flaw detector , eddy curent flaw detector ) Hydrostatic test .

Mill Test Certificate : EN10204/3.1B and EN10204/3.2 Certificat .

Third Party Inspection : SGS , BV ,LLoyds etc

API 5CT Tubing

|

Size |

Weight |

OD |

WT |

Connection | ||||||||

|

Steel Grade | ||||||||||||

|

NUE |

EUE |

in |

mm |

in |

mm |

J55 |

L80-1 |

N80 |

C90 |

T95 |

P110 | |

|

1.900" |

2.40 |

- |

1.900 |

48.26 |

0.125 |

3.18 |

PI |

- |

- |

- |

- |

- |

|

2.75 |

2.90 |

1.900 |

48.26 |

0.145 |

3.68 |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

- | |

|

3.65 |

- |

1.900 |

48.26 |

0.200 |

5.08 |

PU |

PU |

PU |

PU |

PU |

PU | |

|

2 3/8" |

4.00 |

- |

2.375 |

60.32 |

0.167 |

4.24 |

PN |

PN |

PN |

PN |

PN |

- |

|

4.00 |

4.70 |

2.375 |

60.32 |

0.190 |

4.83 |

PNU |

PNU |

PNU |

PNU |

PNU |

- | |

|

5.80 |

5.95 |

2.375 |

60.32 |

0.254 |

6.45 |

- |

PNU |

PNU |

PNU |

PNU |

PNU | |

|

6.60 |

- |

2.375 |

60.32 |

0.259 |

7.49 |

- |

P |

- |

P |

P |

PNU | |

|

7.35 |

7.45 |

2.375 |

60.32 |

0.336 |

8.53 |

- |

PU |

- |

PU |

PU |

- | |

|

2 7/8" |

6.40 |

6.50 |

2.875 |

73.02 |

0.217 |

5.51 |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

7.80 |

7.90 |

2.875 |

73.02 |

0.276 |

7.01 |

- |

PNU |

PNU |

PNU |

PNU |

PNU | |

|

8.60 |

8.70 |

2.875 |

73.02 |

0.308 |

7.82 |

- |

PNU |

PNU |

PNU |

PNU |

PNU | |

|

9.35 |

9.45 |

2.875 |

73.02 |

0.340 |

8.64 |

- |

PU |

- |

PU |

PU |

PNU | |

|

10.50 |

- |

2.875 |

73.02 |

0.392 |

9.96 |

- |

P |

- |

P |

P |

- | |

|

11.50 |

- |

2.875 |

73.02 |

0.440 |

11.18 |

- |

P |

- |

P |

P |

- | |

|

3 1/2" |

7.70 |

- |

3.500 |

88.90 |

0.216 |

5.49 |

PN |

PN |

PN |

PN |

PN |

- |

|

9.20 |

9.30 |

3.500 |

88.90 |

0.254 |

6.54 |

PNU |

PNU |

PNU |

PNU |

PNU |

- | |

|

10.20 |

- |

3.500 |

88.90 |

0.289 |

7.34 |

PN |

PN |

PN |

PN |

PN |

PNU | |

|

12.70 |

12.95 |

3.500 |

88.90 |

0.375 |

9.52 |

- |

PNU |

PNU |

PNU |

PNU |

- | |

|

14.30 |

- |

3.500 |

88.90 |

0.430 |

10.92 |

- |

P |

- |

P |

P |

PNU | |

|

15.50 |

- |

3.500 |

88.90 |

0.476 |

12.00 |

- |

P |

- |

P |

P |

- | |

|

17.00 |

- |

3.500 |

88.90 |

0.530 |

13.46 |

- |

P |

- |

P |

P |

- | |

|

4" |

9.50 |

- |

4.000 |

101.60 |

0.226 |

5.74 |

PN |

PN |

PN |

PN |

PN |

- |

|

10.70 |

11.00 |

4.000 |

101.60 |

0.262 |

6.65 |

PU |

PU |

PU |

PU |

PU |

- | |

|

4 1/2" |

12.60 |

12.75 |

4.500 |

114.30 |

0.271 |

6.88 |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

15.20 |

- |

4.500 |

114.30 |

0.337 |

8.56 |

- |

P |

- |

P |

P |

- | |

|

17.00 |

- |

4.500 |

114.30 |

0.380 |

9.65 |

- |

P |

- |

P |

P |

- | |

|

18.90 |

- |

4.500 |

114.30 |

0.430 |

10.92 |

- |

P |

- |

P |

P |

- | |

|

21.50 |

- |

4.500 |

114.30 |

0.500 |

12.70 |

- |

P |

- |

P |

P |

- | |

|

23.70 |

- |

4.500 |

114.30 |

0.560 |

14.22 |

P |

P |

P |

- | |||

|

26.10 |

- |

4.500 |

114.30 |

0.630 |

16.00 |

- |

P |

- |

P |

P |

- | |

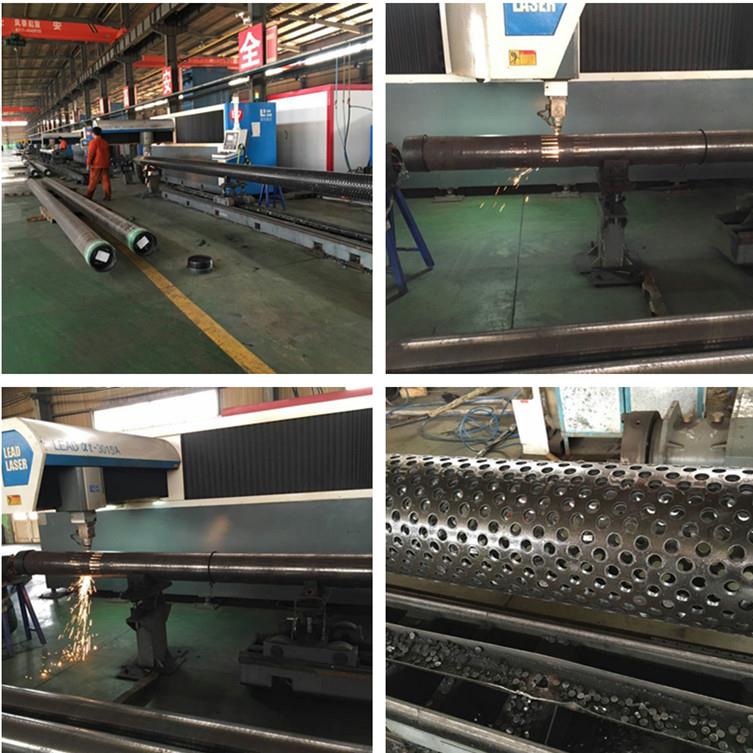

Produce Equipment:

Certificate:

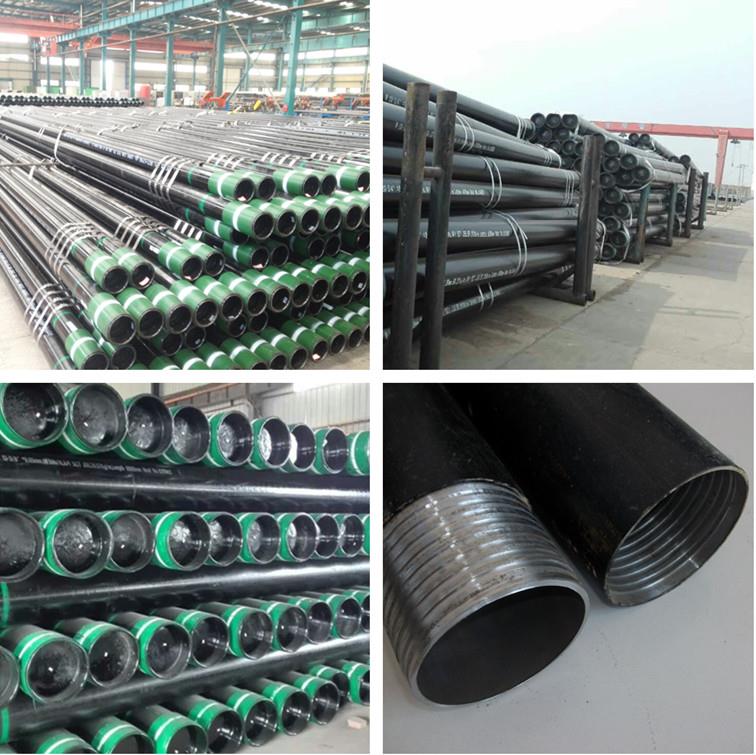

Products:

Inspection:

Part of our Clients:

Why Choose Us:

1: 120 KM from our factory to Tianjin Seaport, Low cost for transport.

2: Professional before-sales sevice and export experiences .

3: Advanced equipment and professional technology

4: Produce Scope almost have all kinds of steel pipe, One-Stop Purchase.

5: Best quality with competitive price .

6: Thoughtfull after -sales service

7: 30,000 Tons stock pipe for normal size ,Shortest delivery time.

FAQ:

1: Q: What kind of connection of the tubing and casing pipe do you have ?

A : Stabdard Coupling ; Special Space Coupling ;Special Bevellde Coupling ;API Improved Seal-Ring Coupling(SR13) ;Combination Coupling or Special Diameter Coupling ; Pup Joint or Connector:All Size,thread or their combination of tubing and casing are supplied.

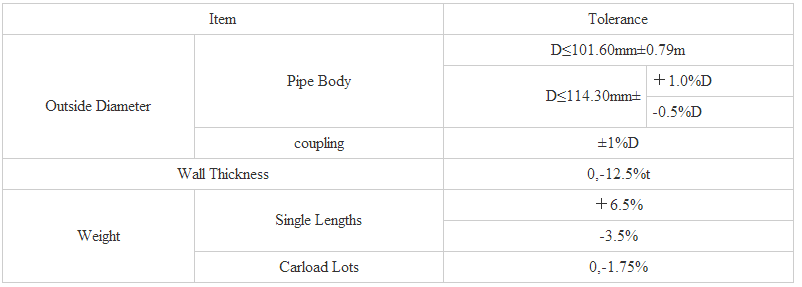

2: Q:What's the Dimensions and Tolerances of the oil tubing and casing ?

A: Please follow the standard as below form :

3: Q : How long for the guarantee period ?

A : Guarantee period can delay to 30 days after clients recieved the pipe in the destination port .

Latest News:

Caing pipe is large diameter pipe that serves as the structural retainer for the walls of oil and gas wells , or well bore . It is inserted into a well bore and cemented in place to protect both subsurface formations and the well bore from collapsing and to allow drilling fluid to circulate and extraction to tak place . Steel casing pipes have smooth wall & minimum yield strength of 35000 psi .

Tubing is the pipe used for the transportation of crude oil and natural gas from an oil or gas layer to the surface after drilling is complete . It is made to withstand the pressure generated from the extraction process . Tubing is manufactured in the same way as casing ,except that an additional process know as "upsetting " is applied to thicken the pipes .